RECOMMEND SOLUTIONS

RELATED PRODUCTS

Four-Faith's 5G Full-Connect Factory One-Stop Solution Goes Live, Shaping the Sustainable Future of Industrial Development

Date:2024-05-17 16:30:09

Policy Background

In September 2022, to accelerate the deep integration of new technologies, new scenarios, and new models of "5G + Industrial Internet" into various fields and links of industrial production, the Ministry of Industry and Information Technology issued the "5G Fully Connected Factory Construction Guidelines," proposing to promote the construction of 5G fully connected factories for thousands of enterprises, establish 1000 classified and graded, distinctively featured factories, create 100 benchmark factories, and promote the deep development of 5G integration applications.

As of now, China has over 10,000 "5G + Industrial Internet" projects. With the continuous promotion of large-scale applications, 5G factories are being established one after another. Typical scenarios are gradually moving from peripheral auxiliary links to core production links, continuously unleashing cumulative effects, and effectively promoting the cultivation and development of new productive forces.

Continuous Innovation! Four-Faith Vigorously Promotes the Deep Expansion of Industrial Production.

With over a decade of experience in the Internet of Things (IoT) field, Four-Faith adheres to the concept of continuous innovation. It actively promotes the high-quality development of "5G + Industrial Internet" in various fields and links such as research and development design, production manufacturing, testing monitoring, warehousing logistics, and operation management. It continuously expands new technologies, new scenarios, and new models into various fields and links of industrial production, continuously cooperating with industry users to empower the landing of 5G AIoT industry application projects.

Taking typical representatives of industrial Internet as an example, the 5G fully connected factory is a hot topic in manufacturing enterprises. By constructing intelligent factories at the production line, workshop, and factory levels, upgrading unmanned production lines, and creating scenarios such as intelligent production lines and smart warehouses, enterprises can achieve cost reduction and efficiency improvement.

Smart Manufacturing Upgrade! Four-Faith 's 5G Fully Connected Factory Creates Benchmark Enterprises

The 5G fully connected factory fully utilizes the integration of new generation information and communication technologies represented by 5G to build a new type of industrial Internet infrastructure. It constructs new or transforms production scenes at the production line, workshop, and factory levels to form advanced factories with extensive production unit connections, deep integration of information technology (IT) and operational technology (OT), full utilization of data elements, and efficient empowerment of innovative applications.

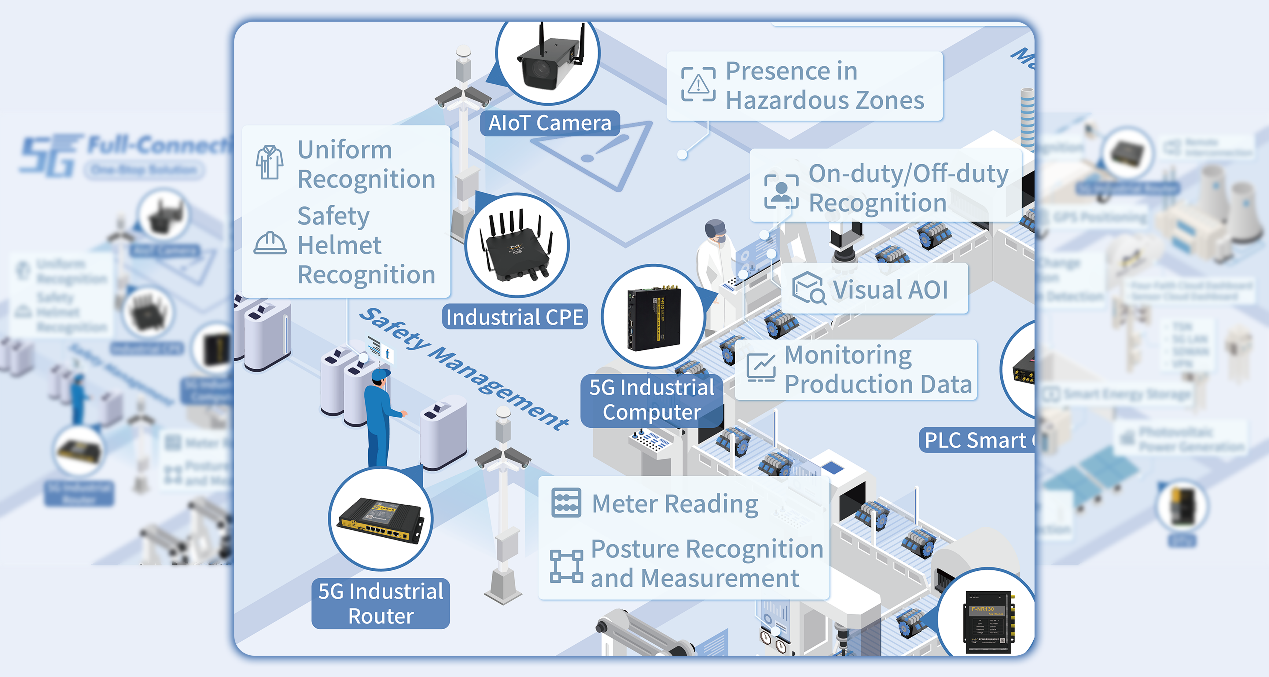

Four-Faith actively explores the practical path of traditional industrial "intelligence transformation and digitalization." It vigorously develops the 5G fully connected factory solution, which is based on emerging technologies such as 5G, AI, and IoT, combined with the development concepts of automation, informatization, intelligence, and digitalization. This solution realizes five majors fully connected intelligent application services: personnel full connection, production full connection, equipment full connection, scenario full connection, and platform full connection. It achieves the mutual integration of 5G with the core business of factory production, promotes the transformation of production and operation modes, enhances the level of factory intelligence, and improves management efficiency. At the same time, it supports enterprises to deploy edge computing nodes on-demand in production scenes, realizing smart interconnection with the platform, meeting the needs of industrial real-time control, on-demand service, on-demand scheduling, data security, etc., promoting the integration deployment of 5G networks and edge computing, and promoting cloud-network-edge-terminal collaboration.

Personnel Full Connection: Achieving intelligent management of factory access

In traditional factory management, manual monitoring and registration are prone to loopholes, and it is difficult to obtain accurate information about the entry and exit of personnel in real-time. Face recognition gates use advanced technologies such as facial recognition, fingerprint recognition, and palm recognition to accurately identify personnel and record their entry and exit times, improving factory security.

In the Four-Faith Full Connectivity Factory Solution, the entrance of the factory is equipped with a facial recognition gate machine embedded with the Four-Faith 5G Industrial Router. Every visitor or staff member entering the premises needs to undergo facial recognition registration. The information from the facial recognition device is transmitted via wired connection to access the factory's private 5G network, where it is compared in real-time with facial data stored on the server. This system controls the entry of personnel and records entry information in real-time, ensuring the security of sensitive areas and reducing potential security risks. Additionally, Four-Faith can provide users with integrated facial recognition gates equipped with 5G communication, enabling real-time monitoring of factory personnel, and ensuring their safety in multiple dimensions.

Simultaneously, the factory area is fully equipped with Four-Faith 5G Industrial Cameras, which can transmit images in real-time via 5G wireless signals without the need for wiring. This facilitates real-time surveillance by different types of factory personnel, enabling them to conduct surveillance anytime, anywhere, and eliminating blind spots within the factory. Furthermore, the Four-Faith cameras are equipped with various edge-side image AI algorithms, enabling intelligent supervision of designated areas. For example, if there is an intrusion in a restricted area, an immediate alert is issued, and mechanical operations in the area can be halted. Real-time warnings are also issued for unauthorized personnel leaving their designated workstations, ensuring personnel safety and maintaining vigilance at various posts within the factory.

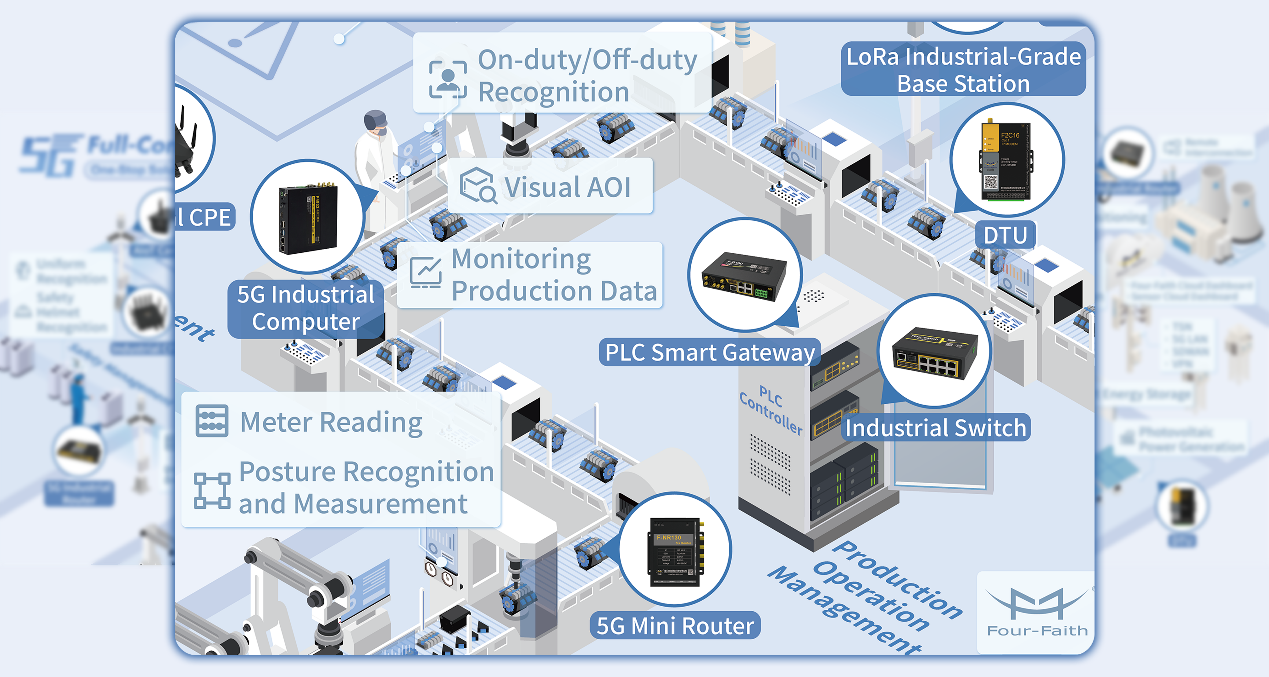

Production Full Connectivity: Achieving refined enterprise production management

In the Four-Faith Full Connectivity Production Workshop, automated production equipment equipped with 5G data acquisition sensors is running efficiently and orderly. Taking the production side of the workshop as an example, various meters and sensor devices are connected via Four-Faith industrial data transmission terminals and industrial routers. They collect real-time data such as pressure gauges, counters, measuring instruments, and posture recognizers and transmit it through the 5G network to the corresponding business platform. Management personnel can monitor production data in real-time through the system backend.

Taking the most widely used PLC in industrial scenarios as a typical case, traditional application methods have long suffered from protocol closure, inability for interoperability among different manufacturers, and the limitation of only being able to complete wired connections. However, with the Four-Faith 5G Industrial Smart Gateway, this device can quickly achieve data transparent transmission while also encapsulating scattered data into protocols. It can then access corresponding applications and SCADA systems in formats such as Modbus or MQTT. Additionally, when paired with Four-Faith industrial-grade switches, it can interface with various brands of PLCs and perform real-time analysis of different protocols, breaking down interoperability barriers and wirelessly integrating PLC devices into the production system using its own 5G communication capabilities. This greatly simplifies the deployment and retrofitting costs of smart factories, making enterprise production and management more scientific and precise.

Furthermore, the Four-Faith 5G Fully Connected Production Workshop also provides users with 5G industrial control computers, control screens, and control boards that run on Linux or Android systems, enabling functions such as edge-side production data statistics, uploading, querying, and control.

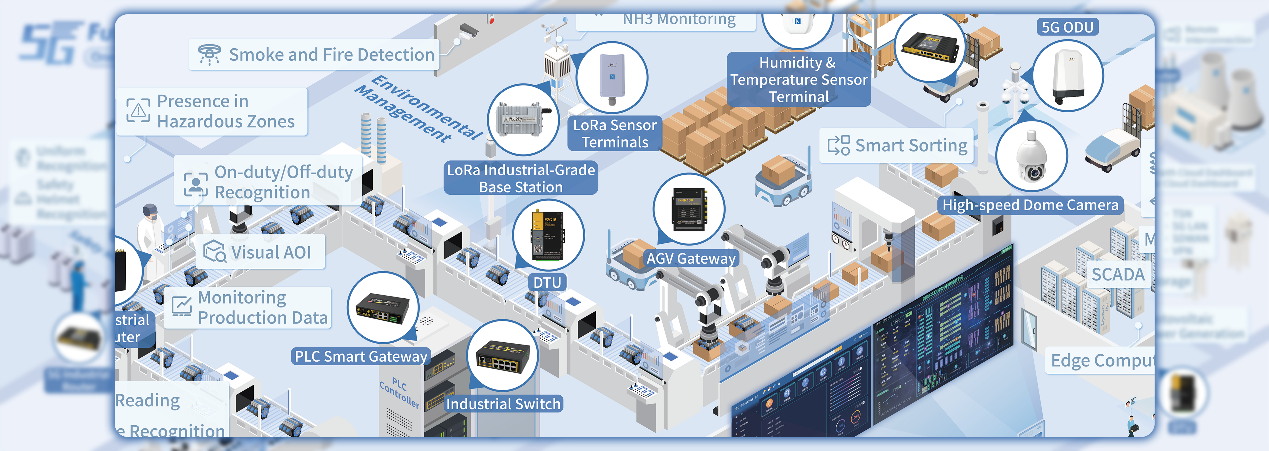

Full Equipment Connectivity: Achieving multidimensional perception in industrial scenarios

In traditional manufacturing plants, each device operates like an isolated island, with production processes being independent of each other, and various types of information unable to communicate or connect.

Following the principle of "Connect All with 5G" in the full connectivity factory, Four-Faith combines 5G technology with production efficiency control, deploying IoT devices and sensors in production equipment and processes. It utilizes 5G networks to monitor and manage production data in real-time, achieving efficient control of the production process.

For example, by using Four-Faith 5G data transmission terminals to connect existing wired devices to a private 5G network, and through 5G gateways, these devices can be transformed into intelligent systems. This allows for real-time monitoring of device operation status, integration, and analysis of various data types, thus rapidly enhancing equipment maintenance and management capabilities.

For outdoor industrial equipment operations, Four-Faith also offers two high-quality products: 5G industrial-grade CPE and 5G ODU. These products boast a high waterproof rating of up to IP68 and are designed for industrial use, ensuring stable operation in most harsh production environments. Additionally, Four-Faith provides 5G AIoT video boxes for internal factory use. These boxes do not require the replacement of existing traditional camera equipment. Simply connecting the existing cameras to the Four-Faith 5G AIoT video box enables edge-side image recognition. Through the combination of data, images, and edge decision-making capabilities, multidimensional perception in industrial scenarios can be achieved. This technology can be widely applied in visual AOI, intelligent sorting, and other scenarios.

Full Scene Connectivity: Achieving efficient communication across all aspects of the factory

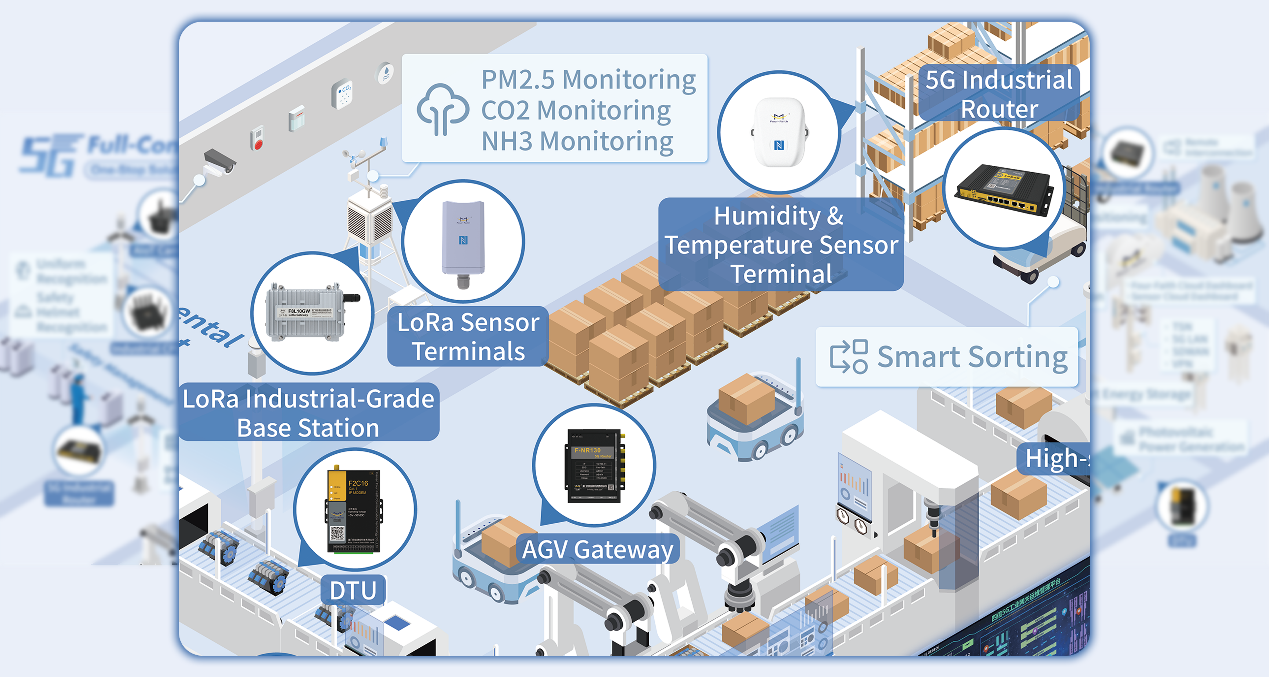

Four-Faith fully utilizes technologies such as IoT, 5G, AI, and big data to seamlessly connect various aspects such as transportation, warehousing, logistics tracking, and measurement settlement. This enables real-time monitoring of shipping, receiving, and measurement data, thereby improving logistics efficiency and resource utilization.

For example, in the transportation and warehousing stages of factories, the Four-Faith 5G terminal series products have been widely used in various segmented scenarios. Taking the most utilized AGV (Automated Guided Vehicle) carts in factories as an example, strong communication capabilities are required to ensure real-time control and management of AGV carts. In order to better adapt to AGV carts within the factory area, Four-Faith has independently developed small-sized 5G industrial routers that can be easily embedded in the carts. This achieves a low-latency, widely connected 5G AGV cart network, while also facilitating data exchange between production line stations, scheduling control desks, and AGV carts. This improves the efficiency of material transportation in the factory.

In warehousing applications, the Four-Faith industrial-grade LoRa solution can be used to achieve real-time data monitoring and risk warning functions, helping managers to promptly identify and resolve operational issues. This solution can monitor warehouse environmental parameters (such as temperature, humidity), equipment operating status, and cargo flow. It sends out alerts when abnormal situations occur, enabling maintenance personnel to take timely measures to avoid losses and delays. Finally, the sensor information in the factory area is transmitted through the 5G LoRa gateway to integrate LPWAN with the private 5G network, achieving centralized collection and management of various data in the factory area, facilitating comprehensive monitoring and precise management of warehouse operations.

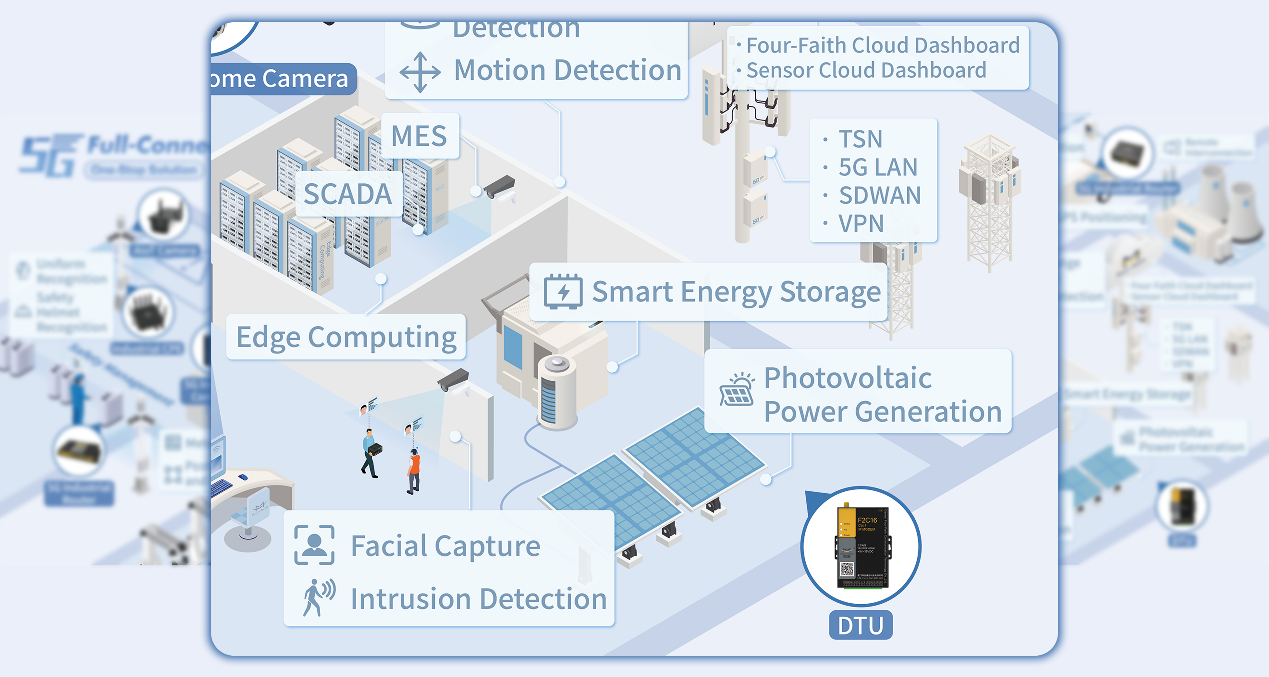

Platform Full Connectivity: Achieving one-stop management connection for the factory

In the Four-Faith 5G Full Connectivity Factory One-stop Solution, whether it's personnel/material entry, full production process, production equipment supervision and control, or outbound transportation vehicle plate and model recognition, the entire path of outbound logistics transportation vehicles can be monitored in real-time through the Four-Faith 5G GPS positioning gateway. This is then complemented by the comprehensive coverage of the Four-Faith 5G series products and application solutions, achieving full connectivity for the factory.

To achieve comprehensive control of multiple devices, the Four-Faith cloud platform has been developed, specifically tailored for industrial equipment. It provides a one-stop device management platform where thousands of Four-Faith 5G devices can be centrally managed. Whether it's remote configuration or batch upgrades, these operations can be performed in the operation and maintenance management center, solving the pain points and difficulties users face in managing large quantities of devices uniformly.

In addition, for the collection and display of various sensor data, Four-Faith has also launched the corresponding business platform - the Four-Faith Sensing Cloud Platform. It features multiple physical models, cloud configuration, and data dashboards, suitable for business displays and data management calls in various smart factories. Its rich API interfaces support secondary development and integration with existing factory systems, enabling alarm linkage and comprehensive management platform functions.

In addition, for the collection and display of various sensor data, Four-Faith has also launched the corresponding business platform - the Four-Faith Sensing Cloud Platform. It features multiple physical models, cloud configuration, and data dashboards, suitable for business displays and data management calls in various smart factories. Its rich API interfaces support secondary development and integration with existing factory systems, enabling alarm linkage and comprehensive management platform functions.

TAGS: 5G Fully Connected Factory 5G product solutions 5G data transmission terminals [Previous Page]

Previous Page:Four-Faith 5G RedCap Application Solution, Accelerating Towards the Vast Ocean of 5G Smart Factories

next page:last_page