The 16th Guangzhou International Modern Industrial Intelligent Equipment Exhibition

Grand opened at Guangzhou Pazhou Poly World Trade Exhibition Hall

on September 12

For 16 years,

The scale of the exhibition,

The scope of the exhibition and the rapid growth of professional visitors,

Greatly promoted the transformation and upgrading of China's manufacturing industry and leapfrog development!

Exhibition Introduction

As an event in the automation production assembly industry, Guangzhou International Modern Industrial Intelligent Equipment Exhibition has been dedicated to promoting industrial automation upgrades for more than ten years. It demonstrates the future of intelligent manufacturing by demonstrating comprehensive automation system integration solutions, leading the development of the industry and promoting new products. The application of new technologies and new concepts in the field of production and assembly makes the production process of the enterprise more systematic, more efficient, smarter and less costly.

With the rise of a series of technologies such as the Internet of Things, big data, artificial intelligence, and consumer demand for customized products, pure automated production has been unable to meet the manufacturing needs of industries such as automobiles, electronics, and home appliances, and more and more manufacturing. Industry and enterprises have embarked on the road of automation to intelligent transformation.

A vision dedicated to making things smarter

Four-Faith have been on the road

to the industrial automation event

On September 12

Industrial Automation Zone - Open the door to the "Industry 4.0"

With the global manufacturing industry moving towards the industrial 4.0, the demand for manufacturing automation has become increasingly prominent. To promote the application of machine vision technology in industrial production, optimizing automation system solutions has become an inevitable choice for enterprises. At this event, Four-Faith teamed up with professional technicians to showcase cutting-edge technologies, R&D products and overall solutions.

On the morning of the same day, the H05 booth received high attention from inside and outside of the industry. The perfect product chain, mature solutions, and intuitive and clear application design drawings attracted a batch of people. The most popular one is. Four-Faith’s Industrial Robot Remote Monitoring System Solution.

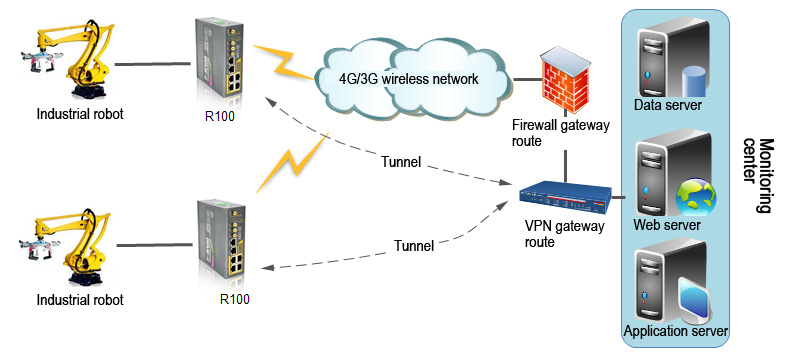

Industrial Robot Remote Monitoring System Solution

1、Program background

With the rapid development of China's economy and the continuous upgrading of industrial upgrading, modern industrial robots are more and more widely used in flexible processing and other production. The stability and reliability of industrial robots and robotic arms on the production line are of great significance to the stability and economic benefits of production.

The industrial robot mechanism is complex and the maintenance cost is high, which puts high demands on the ability of the technical personnel of the production enterprise. The current status of the application of robots puts higher demands on the high-quality service capabilities of industrial robot manufacturers.

The Internet of Things technology and TCP/IP protocol transmit the status and alarm information of industrial robots to the data monitoring center to realize remote data monitoring and fault diagnosis, find problems and solve faults quickly, which is of great significance in modern industrial production.

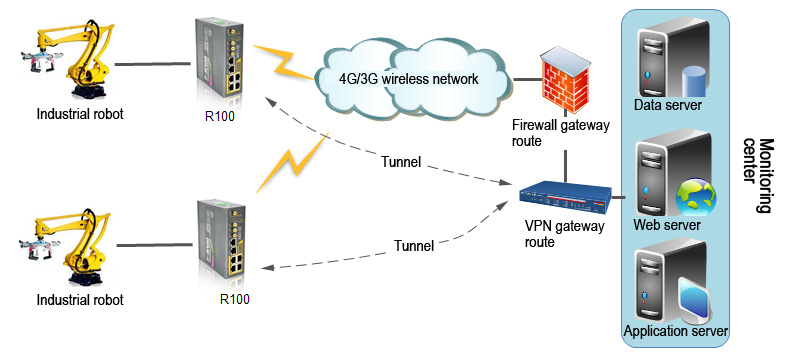

2、System composition

The monitoring center uses ADSL/fiber to access the Internet public network to obtain a fixed public network IP. Build a VPN server. The Four-Faith F-R100 router establishes a VPN tunnel between the VPN client and the server to implement inter networking between the two ends. The acquisition system runs on the database server, which can collect the Ethernet PLC data connected to the Four-Faith router and control the industrial robot. Thereby achieving the purpose of collecting and monitoring the operating state of the industrial robot.

3、System advantage

Stability: It adopts industrial high-performance processor, can withstand the long-term harsh environment test, ensure the smooth communication; reliable network connection, device redial function, can ensure that the device is always online.

Low cost: The wireless data transmission terminal is using operator's 3G/4G network, no network wiring is required, the equipment installation is flexible, and it is not affected by the geographical environment. The single point equipment is cheap, reducing the wiring problem and reducing the cost.

Flexibility and scalability: Standard communication protocols and interfaces for easy installation, commissioning, operation, and maintenance. Simultaneous acquisition and control of multiple robots in a plant.

Timeliness: When the data is abnormal, the monitoring terminal can timely discover and issue instructions to control the industrial robot.

Wonderful moment