The Internet of Things (IoT) has been identified as one of the seven key industries in China’s digital economy. According to IDC analysts, global enterprise-level IoT investment is expected to reach an astounding $1.1 trillion by 2026, while China’s IoT IT expenditure is projected to approach $298.12 billion.

Such a robust IoT market provides a fertile ground for the rapid development of various IoT communication technologies. LoRa technology, in particular, has gained widespread recognition in the industry due to its advantages of low power consumption, long-range communication, flexible networking, and high sensitivity. It has established itself as a leading technology in the low-power IoT communication sector with mature applications across various verticals.

With over a decade of deep involvement in the IoT field, Four-Faith constantly keeps a close eye on market demands from industry users. The company provides IoT communication devices and networking solutions to meet the diverse needs of its partners. Leveraging its innovative R&D capabilities, the Four-Faith R&D team has once again delivered by launching a new series of LoRa modules. These new products boast ultra-low power consumption, ultra-long-distance transmission, high cost-effectiveness, compact size, and strong anti-interference capabilities. They support fully domestic solutions, with upgraded performance and superior quality.

Advantages of Four-Faith LoRa Module Products

- Ultra-long Distance Communication: Tested communication distance > 11.5 KM

- Ultra-high Reception Sensitivity: Reaching an impressive -140 dBm

- Ultra-low Power Consumption: Sleep current < 1.8 µA

- Over-the-air Module Upgrades: Greatly improving project management efficiency

- Excellent Anti-interference Characteristics: More reliable data transmission

- Ultra-compact Size: Suitable for different application scenarios

Application

Compared to traditional modulation technologies, LoRa™ modulation technology offers significant advantages in anti-blocking and selectivity, addressing the limitations of traditional designs that cannot simultaneously achieve long distance, anti-interference, and low power consumption. It can be applied in fields such as smart photovoltaics, smart agriculture, drones, smart buildings, and smart sensing.

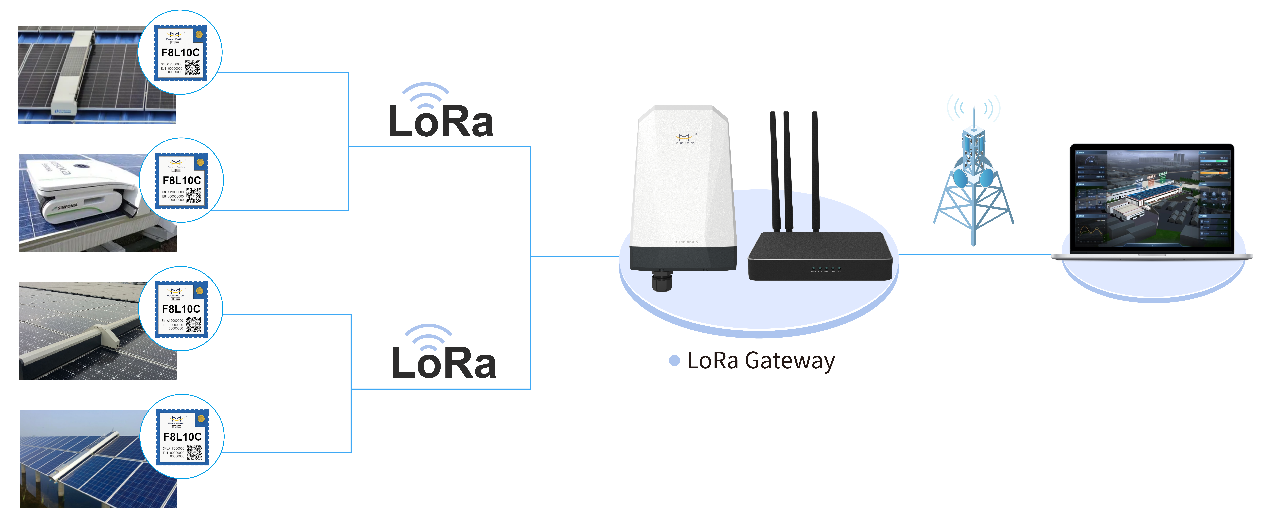

LoRa Photovoltaic Cleaning Robot Application Solution

A photovoltaic cleaning robot consists of three main parts: the mechanical system, the control system, and the sensor system. The mechanical system mainly includes the main frame, brushes, traveling wheels, and side wheels; the control and sensor systems primarily consist of the main control board, motor, communication module, battery, and photovoltaic panel. During routine cleaning tasks, the robot can operate automatically according to preset plans, even in harsh environments, offering high precision and stability.

This solution embeds the LoRa module into the circuit board of the photovoltaic cleaning robot, enabling the server to control the robot’s start and stop functions. When strong winds are detected, the server sends a command to stop the robot. While operating, the robot periodically reports its position and status. Additionally, the server can perform over-the-air (OTA) updates to the robot via the LoRa module, facilitating remote management and maintenance.

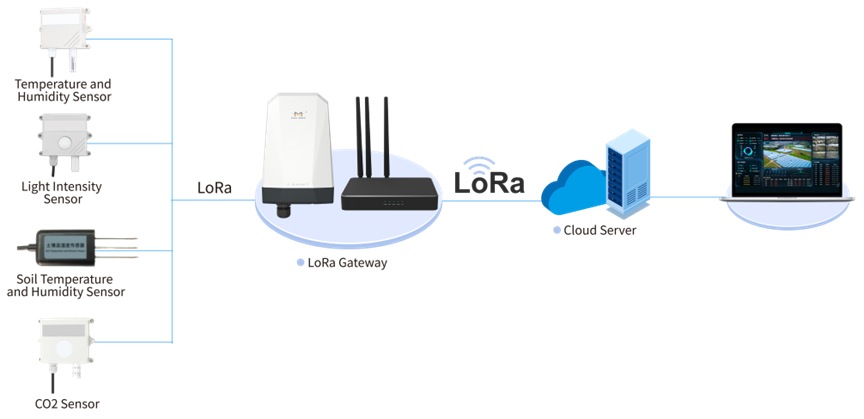

LoRa Smart Agriculture Greenhouse Solution

The Four-Faith smart agriculture greenhouse solution consists of three main components: sensors, a LoRa gateway, and a cloud platform. Sensors collect environmental data such as soil moisture, greenhouse temperature, nutrient levels, pH value, carbon dioxide concentration, air temperature and humidity, atmospheric pressure, and light intensity. This data is transmitted to the cloud platform using the LoRa transmission protocol. The platform then adjusts the temperature control system, irrigation system, and other systems in real-time based on the environmental data. Additionally, the integration of sensors, control systems, and the cloud platform allows for unified interaction. When certain conditions are met, the system can control fans, external shading, internal shading, drip irrigation, side windows, and wet curtains in the greenhouse with a single click, achieving remote and automated management.

Through the cloud platform, real-time monitoring of greenhouse environmental data, surveillance videos, sensor statuses, remote device control, and personnel management can be achieved. Additionally, staff can log into a mobile app to remotely and in real-time view key data for the seedling greenhouse. All collected data is automatically stored on the cloud server, providing more data support for scientific cultivation.

LoRa Photovoltaic Tracking Bracket Solution

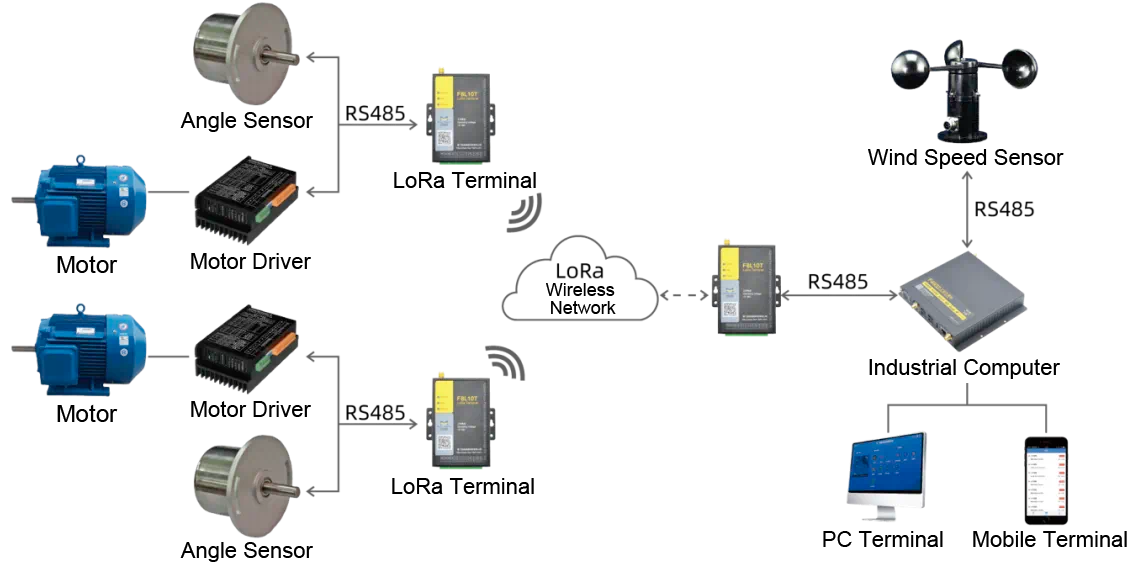

The Four-Faith photovoltaic tracking bracket automatic control system consists of an industrial computer, wind speed sensor, LoRa terminal, angle sensor, motor driver, and motor. The industrial computer serves as the system's central processing unit, responsible for collecting sensor data and issuing control commands based on feedback results and algorithms. The wind speed sensor collects on-site wind speed and wind force data. The LoRa terminal handles the wireless transmission of operational data. The motor driver and motor are responsible for rotating the solar panels.

Through the cloud platform, real-time monitoring of greenhouse environmental data, surveillance videos, sensor statuses, remote device control, and personnel management can be achieved. Additionally, staff can log into a mobile app to remotely and in real-time view key data for the seedling greenhouse. All collected data is automatically stored on the cloud server, providing more data support for scientific cultivation.

LoRa Photovoltaic Tracking Bracket Solution

The Four-Faith photovoltaic tracking bracket automatic control system consists of an industrial computer, wind speed sensor, LoRa terminal, angle sensor, motor driver, and motor. The industrial computer serves as the system's central processing unit, responsible for collecting sensor data and issuing control commands based on feedback results and algorithms. The wind speed sensor collects on-site wind speed and wind force data. The LoRa terminal handles the wireless transmission of operational data. The motor driver and motor are responsible for rotating the solar panels.